MPDS 2

The MPDS 2 is a diesel driven multipurpose unit for a great variety of decontamination jobs. It can be used with up to three lances at the same time, enabling pre-treatment, main treatment and post-treatment to be performed simultaneously with a single unit.

With a capacity of up to 930 litres an hour and a pressure of up to 120 bar, the modular, diesel driven MPDS 2 is a multi-purpose unit for cleaning and decontamination. As well as cold water, it can also produce hot water up to 60 °C and superheated steam up to 150 °C. In the standard version, a great variety of cleaning and decontamination jobs can be performed in simultaneous, dual-lance mode. By integrating two two-component dosing units, the unit can work with numerous commercially available decontamination and cleaning agents, and therefore clean or decontaminate a vast range of different materials. The unit can also be equipped to work with three lances. This enables simultaneous pre-treatment, main treatment and post-treatment using virtually any kind of commercially available decontamination and cleaning agents (additional power source required). An optional integrated electric pump for non-aqueous chemicals, and the two-component dosing unit transform the MPDS 2 into an autonomous, complete decontamination system. The innovative and clear layout of the user interface enables fast and intuitive operation. Easy transport is guaranteed by the unit’s compact and robust design in a stackable tubular frame (crane-loadable) based on the dimensions of a euro pallet compatible. The MPDS 2 is the smallest and most efficient decontamination unit in its class.

Features and benefits

Reliable operation

- Automatic burner shutdown on low water level or overheating

- High-quality drive concept, no belt drive

- High-capacity burner with upright heating coil and continuous ignition with no explosion risk

Easy operation

- Easy to understand pictograms and colour coding

- Fully automated electric start

- Automatic dosing of decontamination and cleaning agents

Simple logistics

- Robust tubular steel frame

- Integrated handles, forklift pockets and crane lifting gear

- No additional energy source needed

High energy efficiency

- For use either standalone as a generator, or in conjunction with high pressure

Simple maintenance

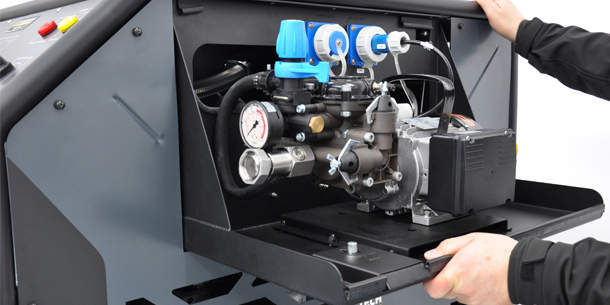

- Components are easily accessible

- Intelligent service software for rapid fault diagnosis during servicing

High flexibility

- Almost any commercially available cleaning and decon agent can be applied at high pressure (including GDS 2000)

- Simultaneous operation of 2-3 lances

- Can be used with virtually all commercially available cleaning and decon agents

Specifications

Technical data

| Cold water - high pressure (bar) | 110 |

| Cold water - flow rate (l/h) | 1500 |

| Steam - temperature max. (°C) | 140 |

| Dimensions (L x W x H) (mm) | 1200 x 800 x 1100 |

| Weight (kg) | 400 |

Easy Operating System

Thanks to the intuitive operating system, the MPDS 2 is easy to operate. The individual functions of the device can be easily identified by means of simple pictograms and colour codes for the various chemicals. Thanks to its quick coupling systems, hose connections can be made quickly, making the system even faster to use.

Additional Pump

The MPDS 2 can optionally be equipped with an additional pump, which enables the application of non-aqueous decontamination agents parallel to high-pressure operation. This increases the flexibility of use and also reduces costs, as no further equipment is required for the discharge of nonaqueous decontamination agents.